利用工业计算机断层扫描(工业CT)测量技术进行在线过程控制

利用工业计算机断层扫描(工业CT)测量技术进行

Writer: admin Time:2021-02-09 15:14 Browse: ℃

利用工业计算机断层扫描测量技术进行在线过程控制

ZEISS VoluMax

高通量的计算机断层扫描技术

Upgrade to productivity

ZEISS VoluMax F1500 thunder

Detect defects reliably inside components without having to sacrifice maximum throughput? This is possible with the ZEISS VoluMax F1500 thunder computer tomograph, which is the first of its kind to be fully integrated into the production line, allowing the fastest 100% inspection.

在生产过程中直接进行测试

ZEISS 在线 CT 扫描机可在生产过程中 100% 检验已加工的塑料部件和轻量化金属组件–即使在恶劣的生产环境中也是如此。该 CT 扫描机会自动输出测量结果是否合格,进而挑出异常的工件。进行 CT 连续检测过程中,系统可以捕获及储存大量不同的产品特征

重大的测量项目经验

许多塑料、金属和复合材料组件的 CT 检验项目已采用 ZEISS VoluMax 系统,例如:ZEISS VoluMax CT 扫描机已用于检验塑料部件的尺寸稳定性、检查汽缸盖内是否有空腔或型砂残留,并也已用于检验安全气囊是否正确安装。ZEISS VoluMax CT 解决方案也适用于 100% 在线检验和随机样本的在线大量检测。

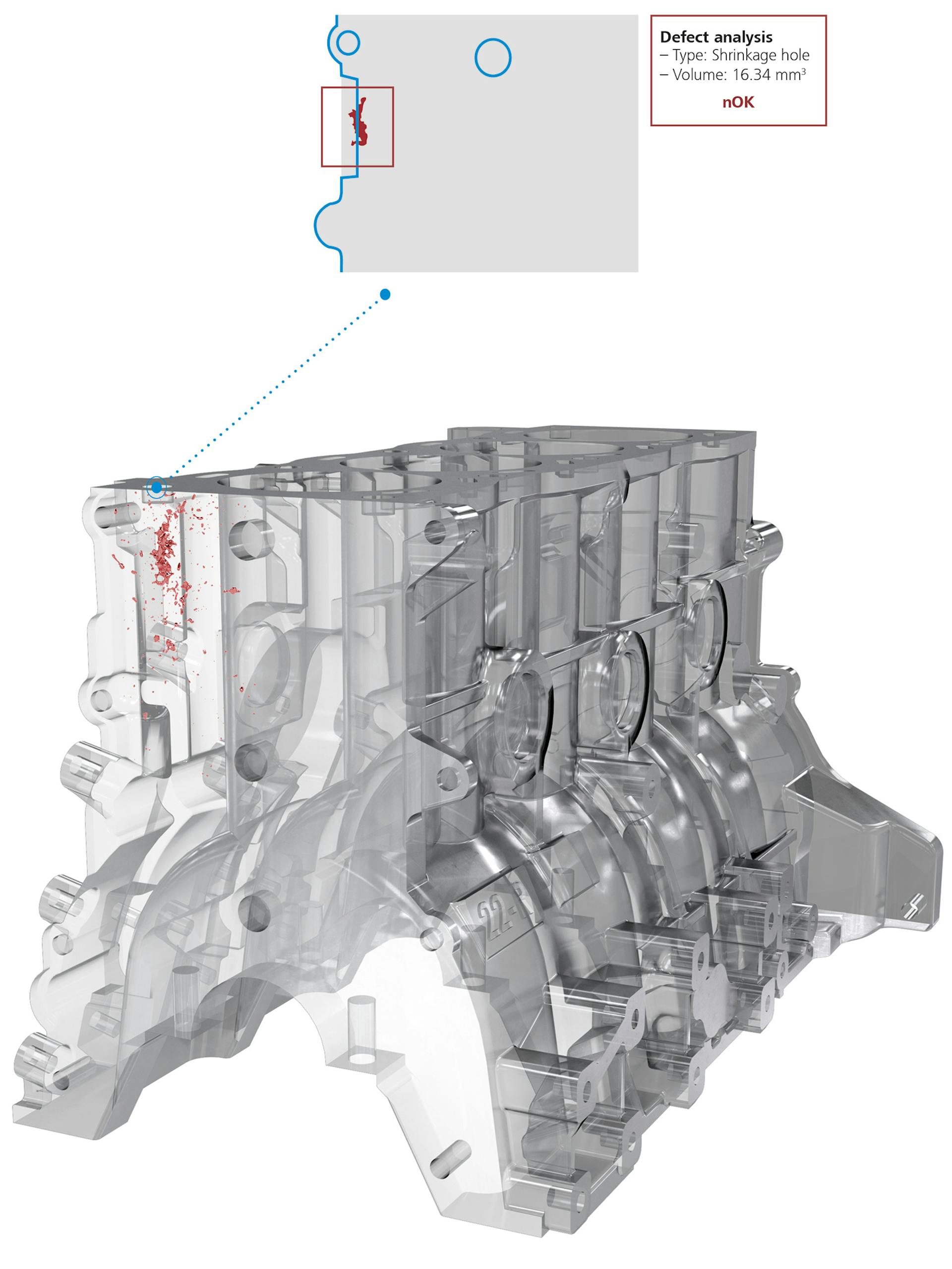

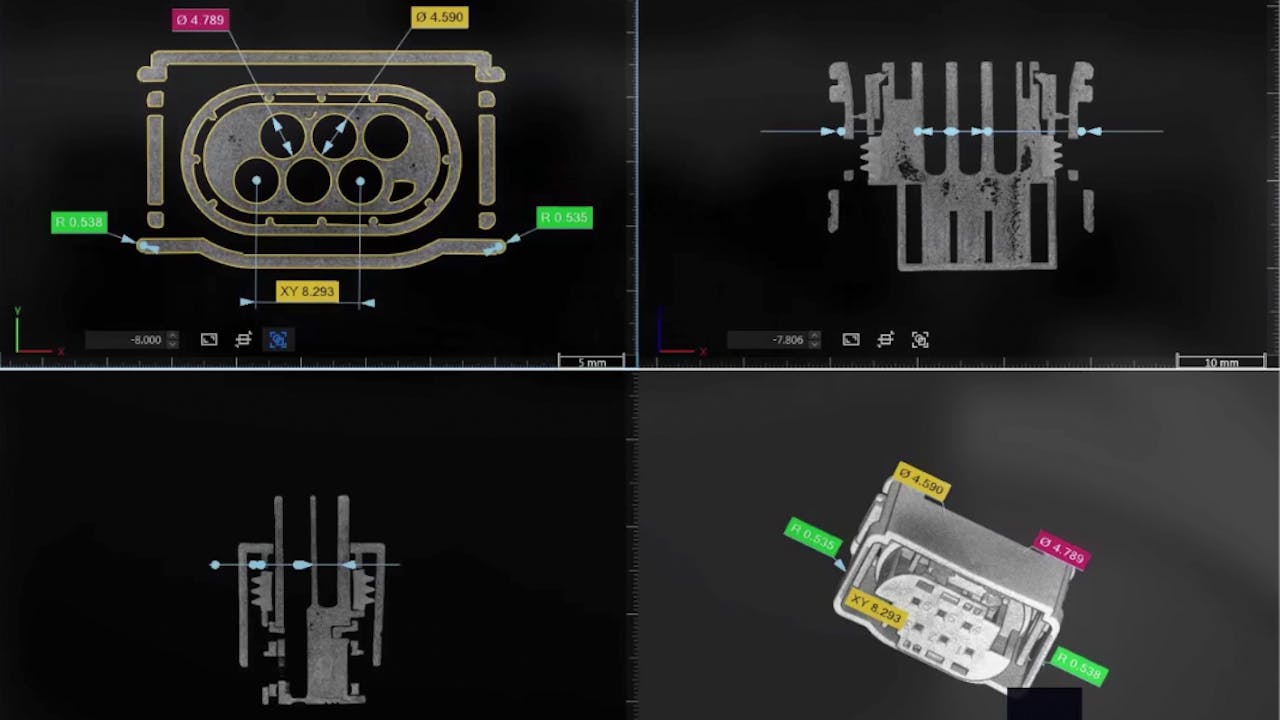

Advanced software solutions for fully automated testing in the line

With ZEISS software, you can use the ZEISS VoluMax CT systems efficiently and exploit their full potential. The ZEISS Automated Defect Detection (ZADD) software uses the CAD model to automatically detect, localize, classify and evaluate whether there are any defects within your components that will impair their quality after processing. Defective components are automatically sorted out to save the costs of unnecessary further processing. The ZEISS PiWeb data management software recognizes repeated occurrence of defects, which allows early intervention in the casting process and thus reduces scrap and costs.

A significant advantage of computed tomography is that it can replace several costly individual tests. Several smaller components can be recorded in one scan and automatically evaluated with regard to dimensional accuracy. This enables a high throughput in productio n.

n.

Software for the analysis and visualization of industrial computed tomography

尽早发现缺陷

蔡司X射线系列适用于轻金属铸造

敢于查看部件内部

联系我们

手机: 0512-67138589

电话: 13285197872

邮箱: zb_1234@163.com

地址: 苏州吴中区东吴南路73号